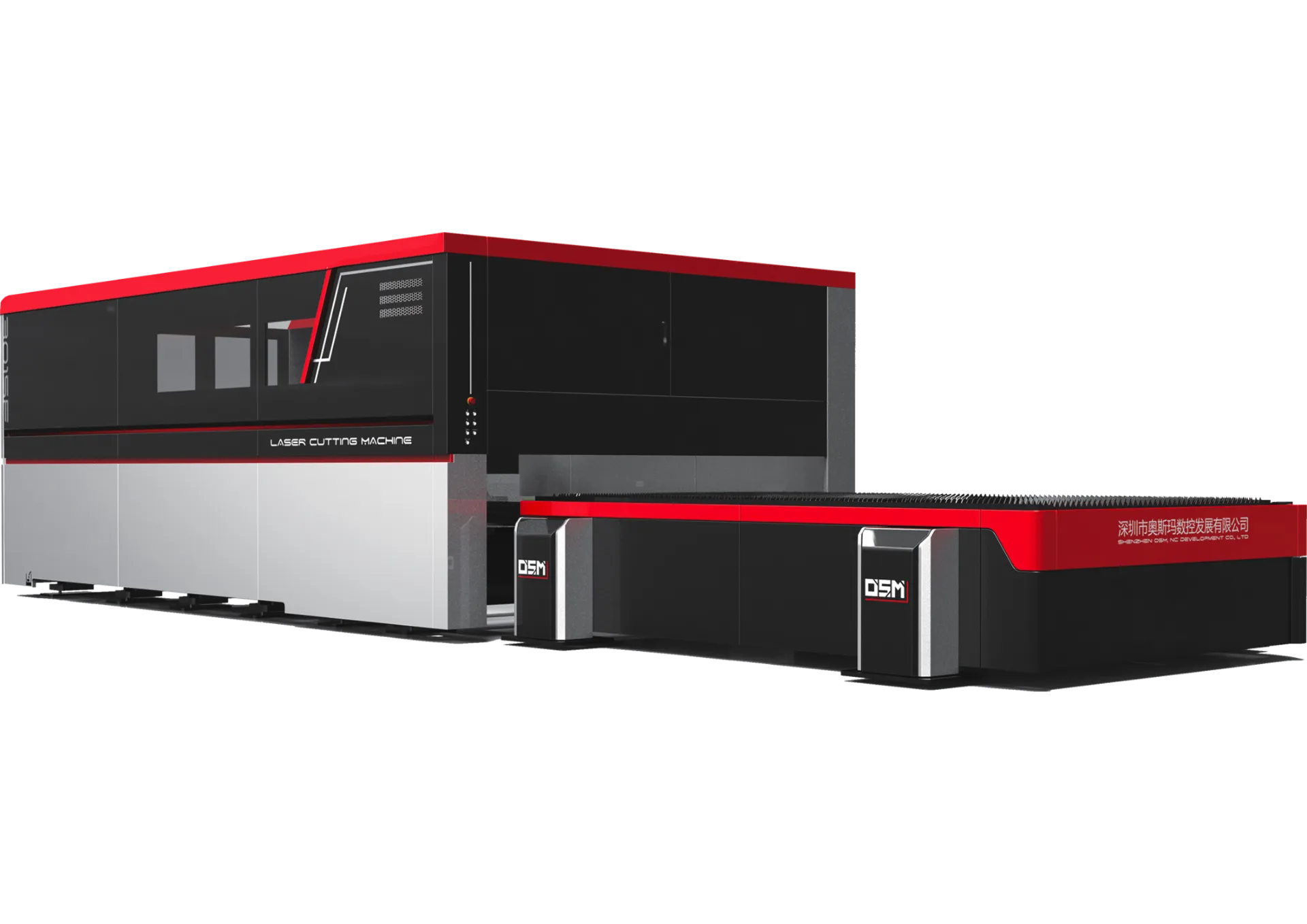

Model: SE Series

Honors: National High-Tech Enterprise, 54 Intellectual Property Rights & Patents, ISO Quality System Certification, EU CE & China 3C Certifications

Address: No. 377, Haitian Avenue, Hecheng Street, Gaoming District, Foshan City, Guangdong Province, China

Process:

All-Electric Drive, Zero Hydraulic System

Over 30% Energy Savings, Low Maintenance, Minimal Operating Costs

Ultra-Fast Dynamic Response (Millisecond Torque Feedback)

Product Overview:

The SE Series top-drive electric servo bending machine utilizes dual servo motor direct-drive high-precision heavy-load ball screws paired with a closed-loop control system for real-time screw position calibration, achieving ±0.02mm repeat positioning accuracy and millisecond-level torque response. By eliminating traditional hydraulic systems, it removes oil leakage risks, reduces structural complexity, and delivers:

Its automated multi-axis servo backgauge system supports 1/2/4-axis configurations with intelligent CNC path planning, enabling rapid positioning and continuous bending for complex workpieces. Optimized for high-speed thin-sheet processing, this machine redefines precision and efficiency in sheet metal forming.

Applications:

Tailored for premium manufacturing sectors including:

Automotive: Precision sheet metal components, lightweight body panels

New Energy: Battery enclosures, hydrogen fuel cell parts

5G Telecom: Filter chambers, antenna brackets

Aerospace: Titanium alloy structural components

Engineered for aluminum, stainless steel, and high-strength steel processing, the SE Series meets full-lifecycle demands from single-piece customization to mass production. With zero hydraulic contamination, ultra-low noise (≤70dB), and 40% higher energy efficiency, it is ideal for cleanroom environments and industries with stringent hygiene standards, such as medical device manufacturing and electronics assembly.

Why Choose SE Series?

Clean, Efficient, and Cost-Effective All-Electric Design

Sub-Micron Precision for Critical Applications

Seamless Integration with Smart Factory Systems