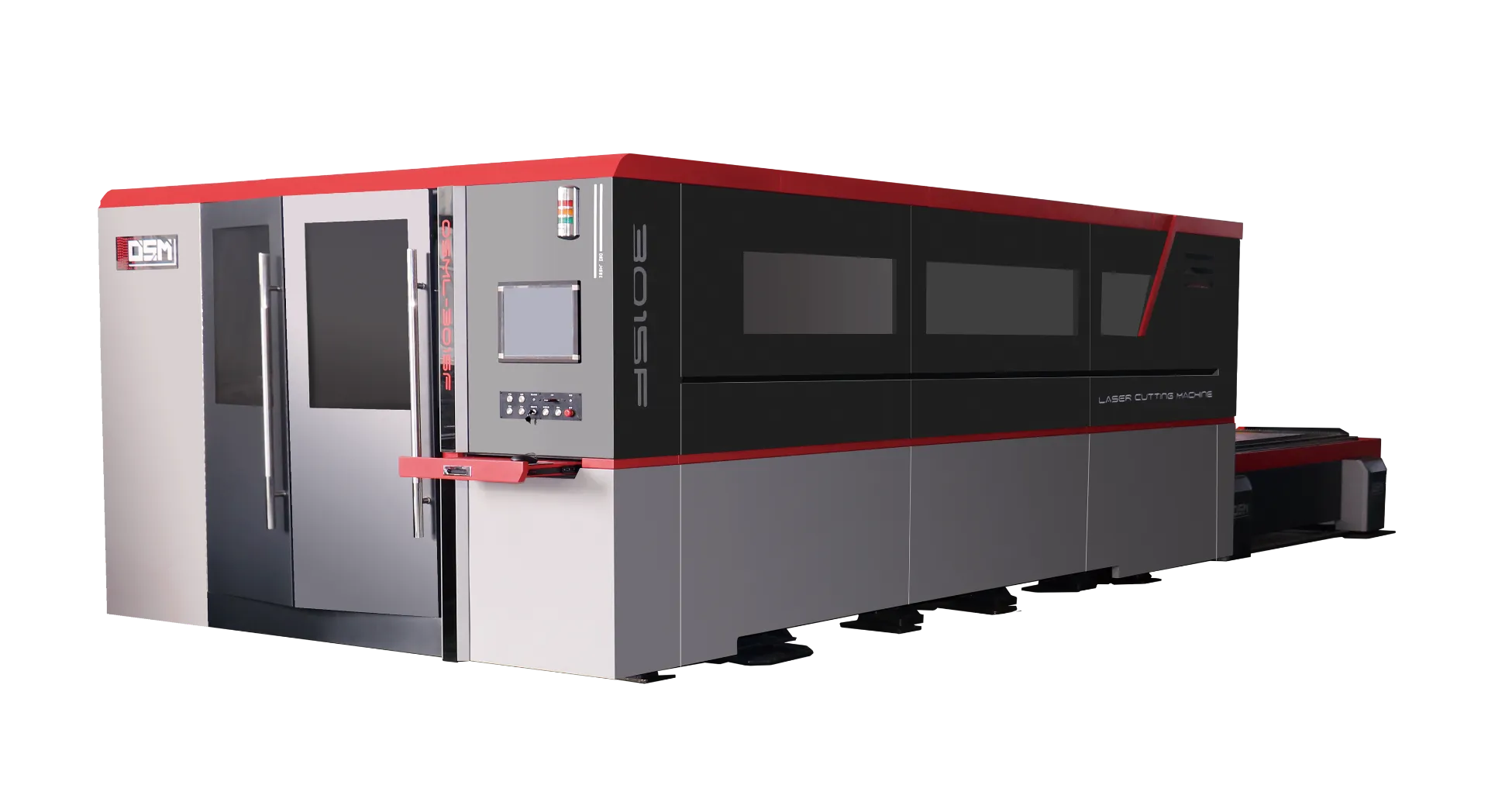

OSM CNC Press Brake

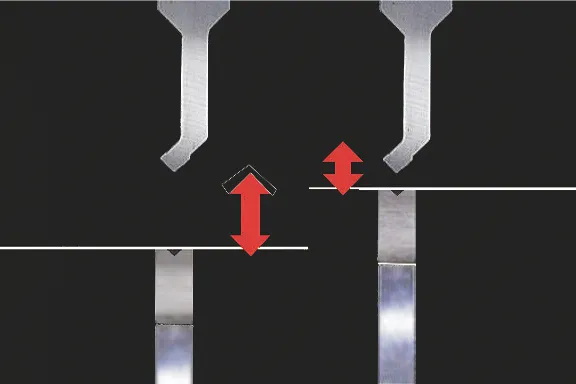

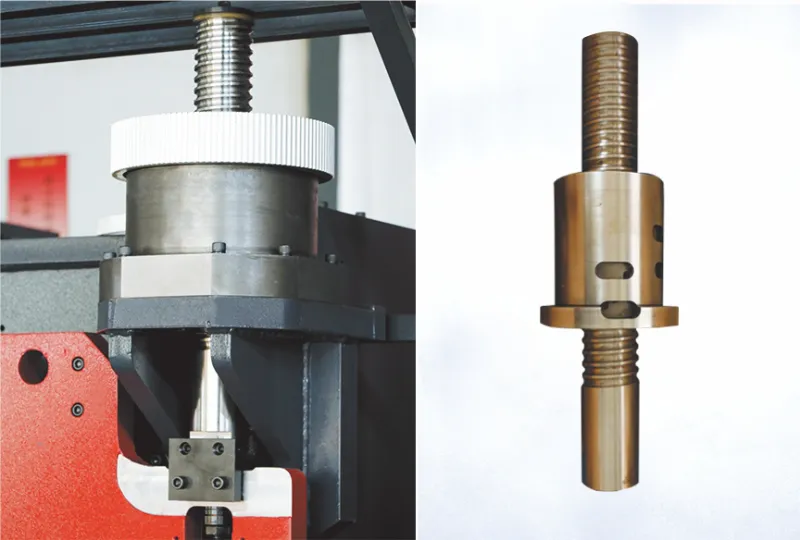

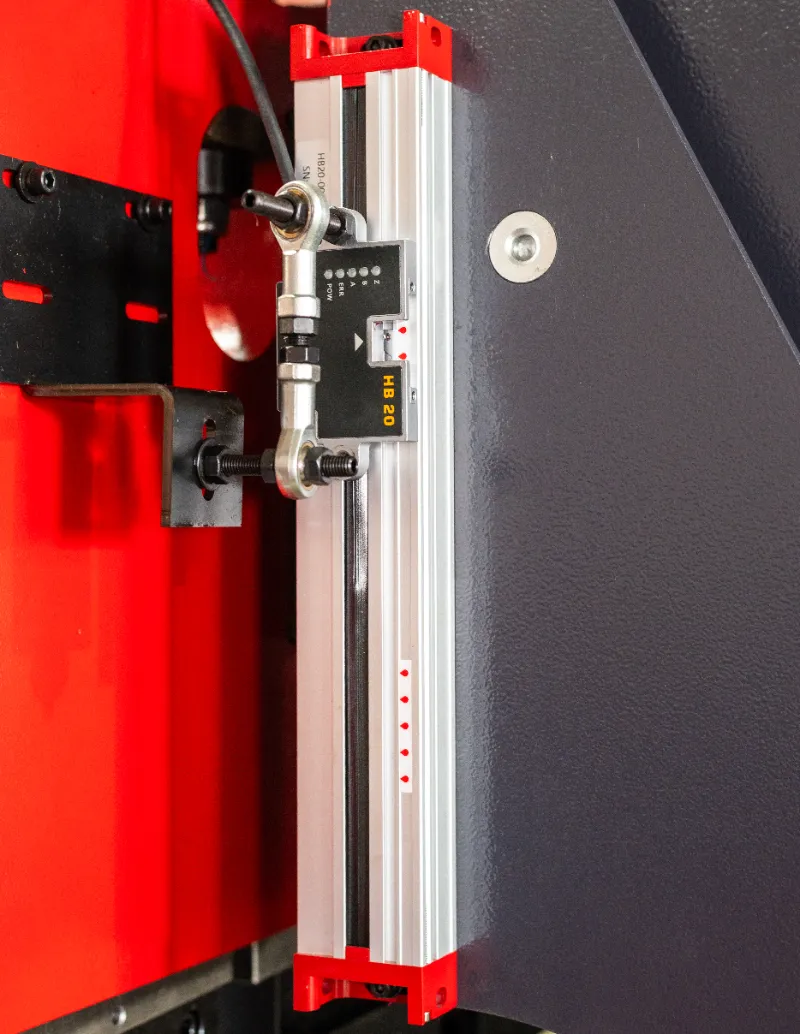

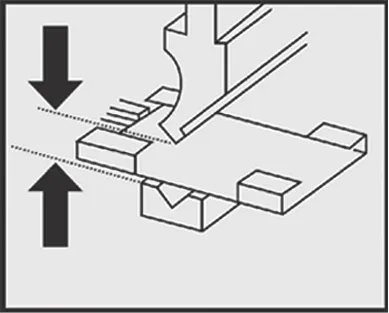

High Precision Bending – Accurate angles, consistent results

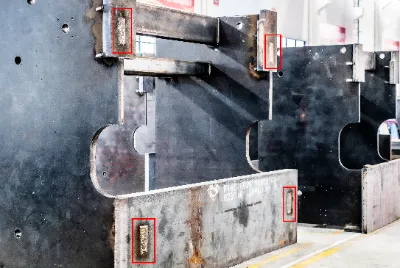

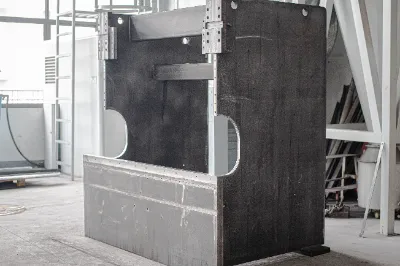

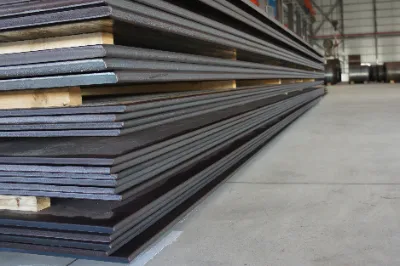

Strong & Durable Structure – Built to last for years

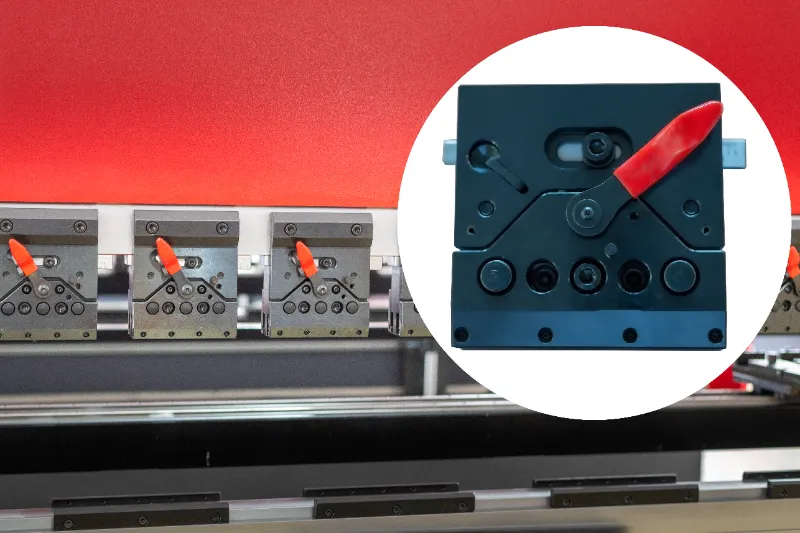

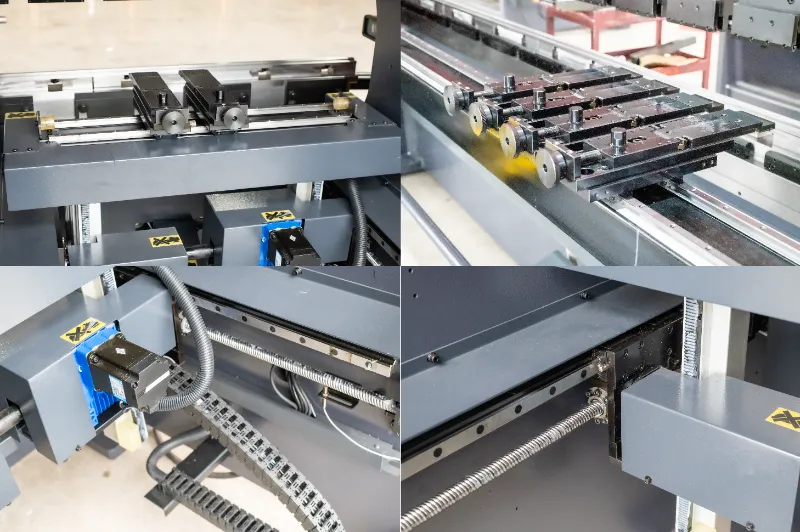

User-Friendly CNC System – Easy to operate, save labor

Energy Efficient – Lower power consumption, cost-saving

Fast Bending Speed – Improve your productivity

Customizable Solutions – Meet your specific needs