OSM press brakes achieve ultra-high precision of ±0.01mm, exemplified in elevator car panel bending where accurate angles and dimensions ensure seamless assembly. The advanced CNC system precisely controls bending parameters (angle, depth, speed) according to elevator component design requirements.

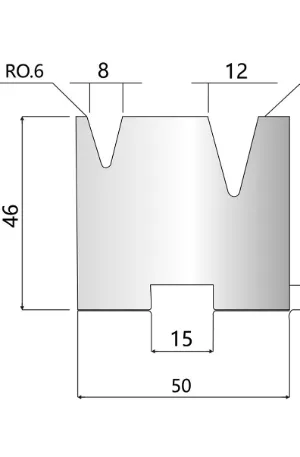

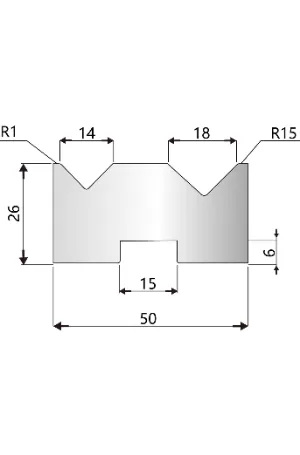

The rapid tooling change system reduces mold replacement time to under 5 minutes, significantly enhancing productivity for elevator industry's diverse, small-batch production. Under frequent bending operations, it achieves 50-80 bends per hour, meeting mass production demands.

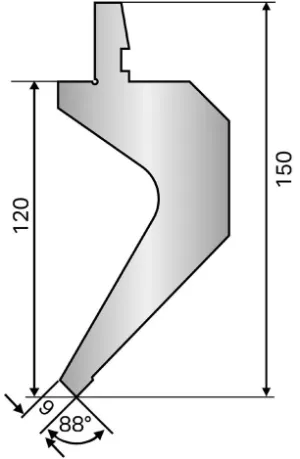

Designed for elevator-grade stainless steel and carbon steel, the machine handles 0.4-12mm thickness ranges effortlessly. Specialized tooling enables precise bending of complex components like curved handrails and shaped door panels.

Equipped with multi-layer safety protections (light curtains, emergency stops), it ensures operator safety. The stable mechanical structure and electrical system enable quick shutdowns during anomalies, minimizing downtime and ensuring continuous elevator production.

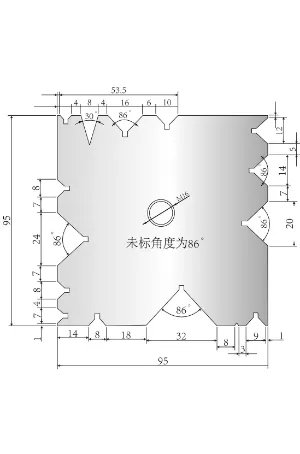

Elevator guide rail bracket shims are small-sized sheet metal components typically made of 0.5-1.0mm stainless steel or cold-rolled carbon steel sheets. The SE series pure electric servo press brake excels in such thin-sheet processing, maintaining stable operation in complex environments while easily handling multiple bending angles—making it a highly efficient tool for thin-sheet bending applications.

Elevator door panel bending processes are generally categorized into short-side bending and long-side bending, utilizing stainless steel plates with thicknesses ranging from 1.2mm to 3.0mm and lengths typically between 1200mm and 2400mm. Due to the relatively long plate dimensions and moderate thickness, manual operation precision requirements are high during machining, leading to elevated labor costs. Flexible bending centers effectively address these challenges, serving as ideal equipment for elevator door panel mass production.

Elevator columns often use strong materials like carbon steel or stainless steel. These columns usually measure over 5.0 mm in thickness. Their weight and need for strength and corrosion resistance makes servo-hydraulic CNC press brake the best option. The machines have an integral welded frame. This design offers exceptional stability and load-bearing capacity. It easily bends large, thick plates. This makes them an efficient tool for thick-plate fabrication.