OSM CNC Press Brake

High Precision Bending – Accurate angles, consistent results

Strong & Durable Structure – Built to last for years

User-Friendly CNC System – Easy to operate, save labor

Energy Efficient – Lower power consumption, cost-saving

Fast Bending Speed – Improve your productivity

Customizable Solutions – Meet your specific needs

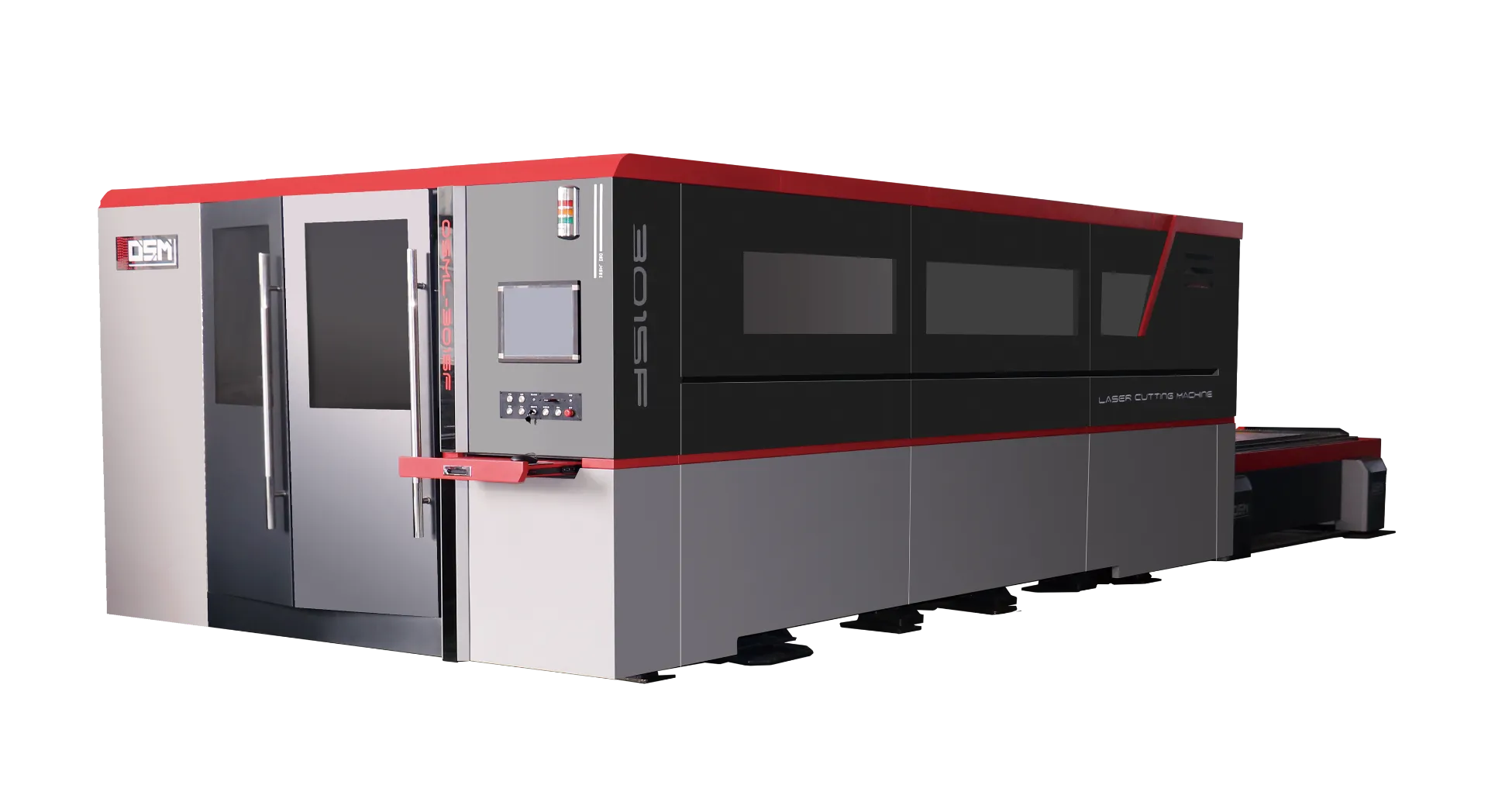

Fiber Laser Cutting Machine

Precise and fast: ±0.05 mm accuracy with a cutting speed up to 10 mm/min.

Energy saving and eco-friendly: high-energy-efficiency laser with no pollution.

Smart control: advanced CNC for automated operation with consistent accuracy.

Flexible use: cuts complex graphics and irregular materials.

OG Series Press Brake Parameter

| Item | Unit | OG-35Ⅱ | |

| Nominal Force | KN | 350 | |

| Workbench | MM | 1200 | |

| Bending Length | MM | 1250 | |

| Colume Distance | MM | 1010 | |

| Stroke Distance | MM | 100 | |

| Max. Daylight | MM | 400 | |

| Approach Speed | MM/S | 56-68 | |

| Bending Speed | MM/S | 1-9.5 | |

| Return Speed | MM/S | 60 | |

| Dimensions(Max.) | Length | MM | 1450 |

| Width | MM | 1350 | |

| Height | MM | 2150 | |

| Mian Motor Power | KW | 3 | |

| Total Power | KW | 5 | |

| Power Supply Cable | M㎡ | 2.5 | |

| Gross Weight (Approx.) | KG | 2100 | |

Industry Applications: new energy, electronics and electrical appliances, 5G products, server racks and cabinets, filing cabinets, kitchenware, range hoods, air purification equipment, etc.

Down-Acting Hydraulic Press Brake: A Cost-Effective Domestic Option

High Efficiency, Consistent Precision

Specifically engineered for metal sheet bending, combining high-speed operation with precision accuracy to deliver desired angles/shapes for both thick and thin plates, ensuring time/labor efficiency and consistent quality.

Versatile Mold for Broad Applications

Utilizing upper/lower dies of various profiles, the system enables complex workpiece fabrication to meet diverse processing requirements, offering flexible adaptation to custom orders.

Integrated Hydraulic System for Reliable Operation

Featuring a down-acting hydraulic system with integrated design, it achieves compact structure, low failure rate, and minimal maintenance requirements for reliable operation.

Dual Guide Structure Ensuring Angular Consistency

Dual safeguards of cylinder side guidance and upper stopper positioning ensure smooth ram movement and precise angle control during every bending cycle.

Automatic Upper Die Crowning for Enhanced Precision

Equipped with wedge-type fine-tuning crowning mechanism and quick-clamp system, it automatically adjusts to material variations to eliminate errors, enhancing consistency and final product yield.

Cost-Effective Domestic Alternative with Dedicated Service

As a down-acting hydraulic press brake, it offers optimal cost-efficiency supported by localized technical assistance and rapid after-sales service, making it the preferred choice for mid-to-high-end users.