Model: SH Series

Product Overview:

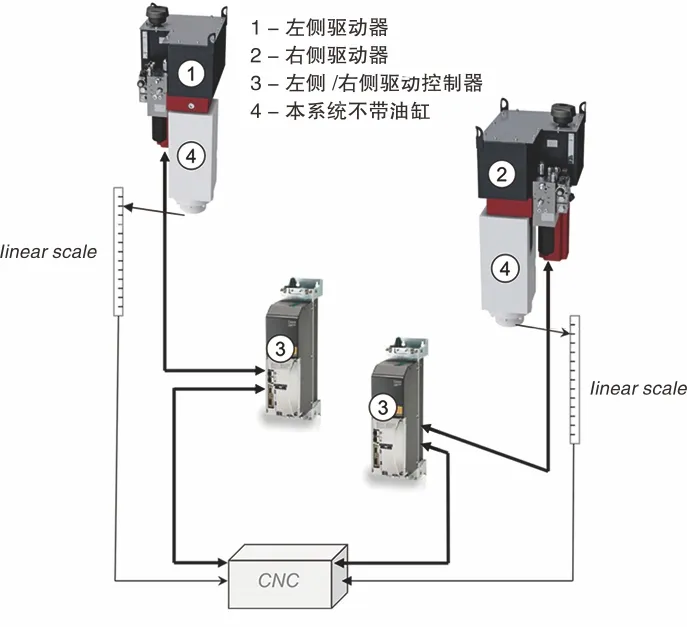

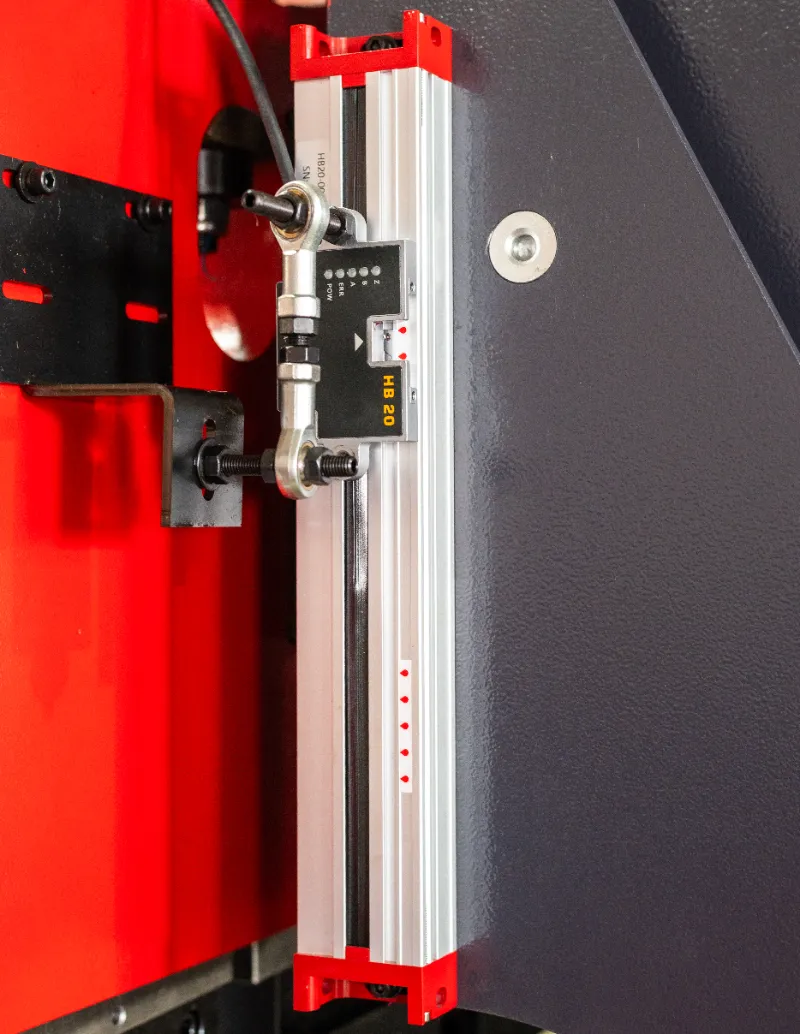

Germany's HAWE oil-electric hybrid drive boosts SH series energy efficiency by 50%, delivering 0.005mm positioning accuracy and cutting power costs by 40%. Crowning mechanism ensures consistent bending precision across 500-3,200mm widths. 5-micron magnetic scale and pressure filter reduce cycle time by 10%, hydraulic oil use by 50%, and noise.

Applications:

SH series targets lightweight automotive parts, new energy batteries, 5G communication frames, and aerospace titanium. Processes high-strength steel, aluminum, and stainless steel, supporting curved surfaces and flexible production. Hybrid energy-saving tech aligns with low-carbon manufacturing.

| Item | Unit | SH-11030 | SH-13030 | SH-17030 | |

| Nominal Force | KN | 1100 | 1300 | 1700 | |

| Workbench | MM | 3200 | 3200 | 3200 | |

| Daylight | MM | 500 | 500 | 500 | |

| Stroke Distance | MM | 200 | 200 | 200 | |

| Return Speed | MM/S | 170-190 | 150-180 | 140-170 | |

| Bending Speed | MM/S | 10-15 | 10-15 | 8-13 | |

| Approach Speed | MM/S | 180-200 | 160-190 | 150-180 | |

| Dimensions(Max.) | Length | MM | 3950 | 3950 | 4000 |

| Width | MM | 1900 | 1850 | 1800 | |

| Height | MM | 2450 | 2550 | 2650 | |

| Total Capacity | KVA | 12.5 | 14.5 | 15 | |

| Single Motor Power | KW | 4.4 | 5.5 | 5.5 | |

| Total Controlled Axes | Pcs | 4+1/6+1 | 4+1/6+1 | 4+1/6+1 | |

| Gross Weight (Approx.) | T | 8.2 | 8.6 | 9.5 | |

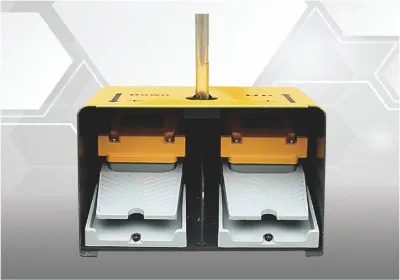

Foot pedal switch reduces operator fatigue while enhancing operational efficiency. With a mechanical endurance exceeding 1 million cycles, it ensures long-term reliability in industrial environments.

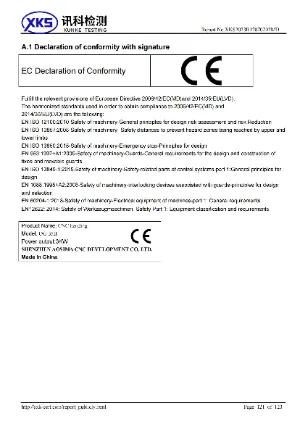

High-sensitivity laser safety system with real-time monitoring capabilities immediately halts ram movement upon obstacle detection, preventing operator injury and fully complying with CE safety standards.

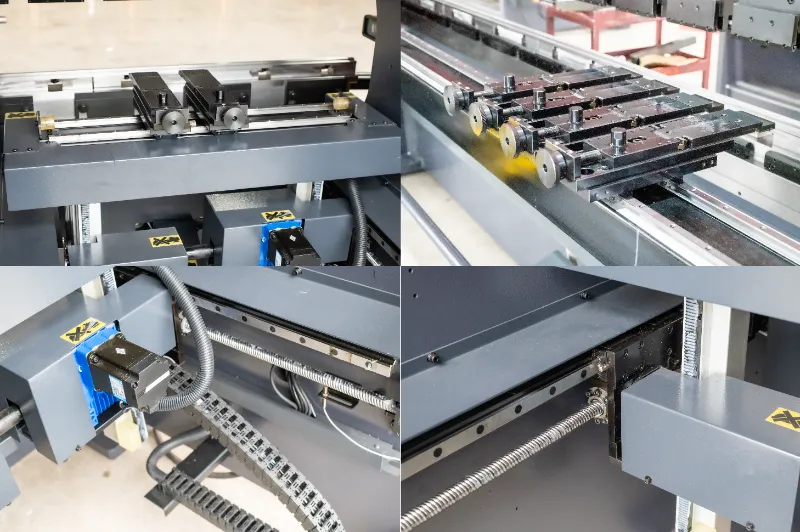

By using the direct control of the digital encoder, the height of the stop of the working table is directly controlled, in order to avoid unnecessary empty travel, greatly improve the production efficiency.

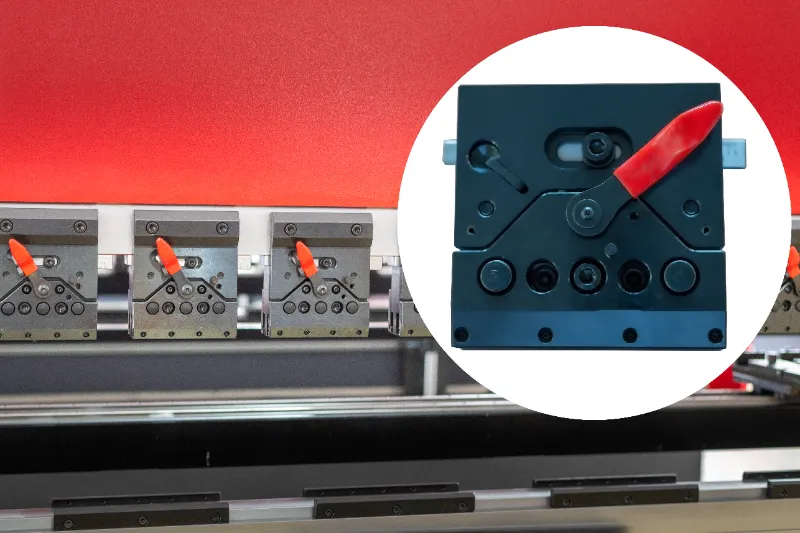

The upper tool quick-clamping device ensures straightforward and stable installation, prevents upper tool displacement, enables rapid release/clamping cycles, and significantly reduces setup time.

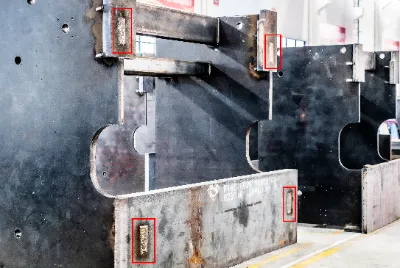

Our press brakes are welded into shape and then machined as a whole using a large gantry CNC machining center, ensuring superior precision and structural integrity.

Compared to traditional welded structures, the nested frame design eliminates distortion and deflection. It ensures stable geometry and maintains machining accuracy over long-term use.

The machine body welding process employs robotic automatic welding combined with manual touch-up welding.Every connection on the press brake frame is welded 10 times, strictly following Multi-layer and multi-pass welding standard for maximum strength and durability.

After the machine body is welded into an integral structure, it undergoes an overall tempering process at a temperature range of 400-650 degrees Celsius, ensuring high consistency in the strength of the machine body.

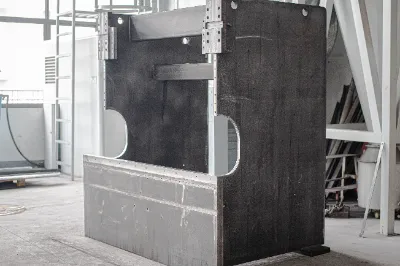

Once the mainframe is integrally fabricated, it is fully sandblasted and coated with one primer layer and two topcoats using eco-friendly water-based paint — ensuring excellent adhesion and a finish that never peels.

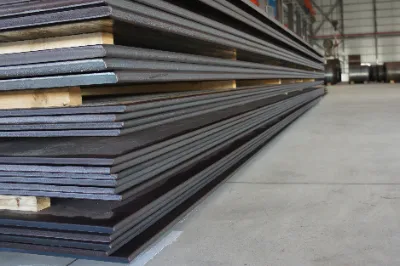

Made by high-manganese steel grades Q355 and Q235, which are of the same high-yield-strength steel type as that used in warships, submarines, and cross-sea bridges

The slow bending function allows you to set the bending speed for easy operation. You can also set the position where slow bending starts and the waiting time between steps, with support for digital settings or manual selection, improving processing flexibility and precision control.

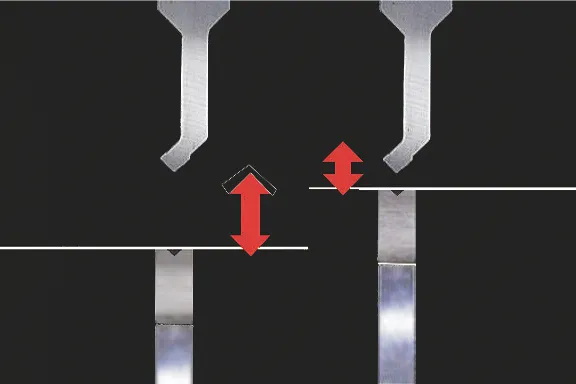

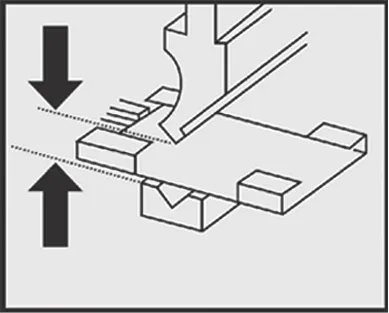

The pull-back and bending function is activated after the mold clamps the material. It first performs an up-and-down movement to confirm that the material is securely clamped, thereby preventing interference with the material during the bending process and ensuring smooth processing.

The circular arc bending function enables automatic arc bending by entering spacing, converting steps into smooth curves with precision and consistency for sheet metal applications.

The line marking bending function ensures precise forming by positioning pre-drawn lines and optimizing parameters, molds, and intelligent systems, enhancing efficiency and consistency.

Features a high-definition color touch screen with embedded PLC, enabling 2D graphical programming, length calculation, and multi-mode operation (graphical tooling up/down, multi-process, telescopic configurations). Supports bending simulation and dual-machine coordination.

Equipped with a high-resolution TFT widescreen display and industrial-grade multi-touch interface for intuitive DELEM UI access. Ergonomic design with shortcut-key operation for simplified programming and user-friendly interaction.

Features a full-touch HMI with 12/15" displays and next-gen controllers, offering high resolution, intuitive interfaces, and smooth operation. Supports 2D graphical programming, 3D bending simulation, DXF file import, efficient tooling editing, and switchable 2D/3D system modes.

Provides comprehensive functionality for press brakes, enabling quick calibration to match machine requirements. Stores multi-step bending processes and product data, supporting manual operation and advanced automation—a powerful yet user-friendly control solution.

The quality and precision of OSM's press brake are outstanding. We’ve been using it for eight months, and it still maintains exceptional accuracy without any deviation. The robust build and excellent craftsmanship make it a top-tier machine!

The energy-saving mode of OSM's press brake is impressive! Compared to our previous equipment, energy consumption has been reduced by 25%, while production efficiency has increased by 30%. It not only saves costs but also aligns with our green manufacturing standards.

We operate OSM’s press brake 24/7, and it remains highly stable with no need for frequent maintenance. Even under high-intensity production, there have been no malfunctions, significantly boosting our productivity! Their service is very good, remote support is always online.

OSM’s intelligent press brake is equipped with an AI recognition system that automatically detects material thickness and adjusts parameters, reducing manual intervention. It handles different materials and sheet metal shapes effortlessly, greatly enhancing production flexibility!