SH Series CNC Servo-Hydralic Press Brake

Model: SH Series

Product Overview:

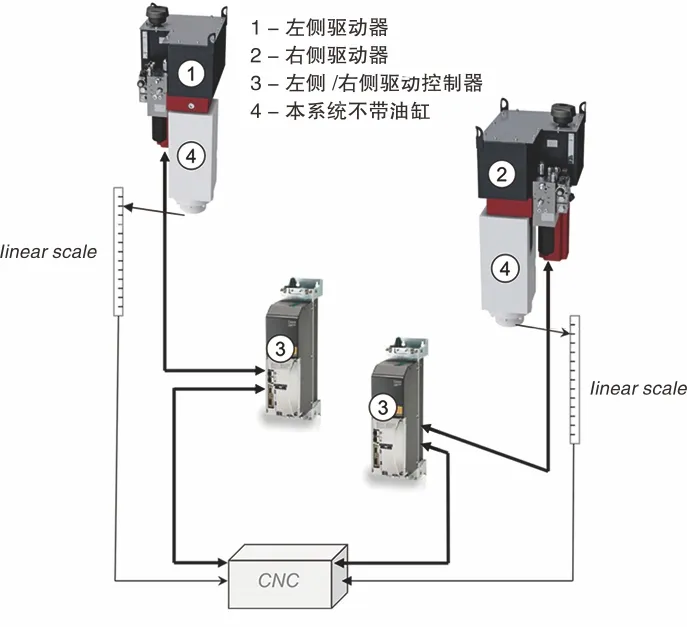

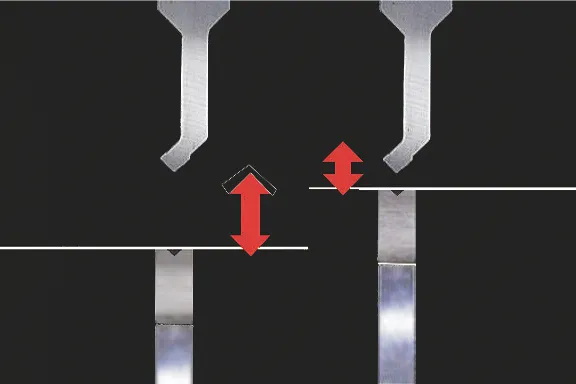

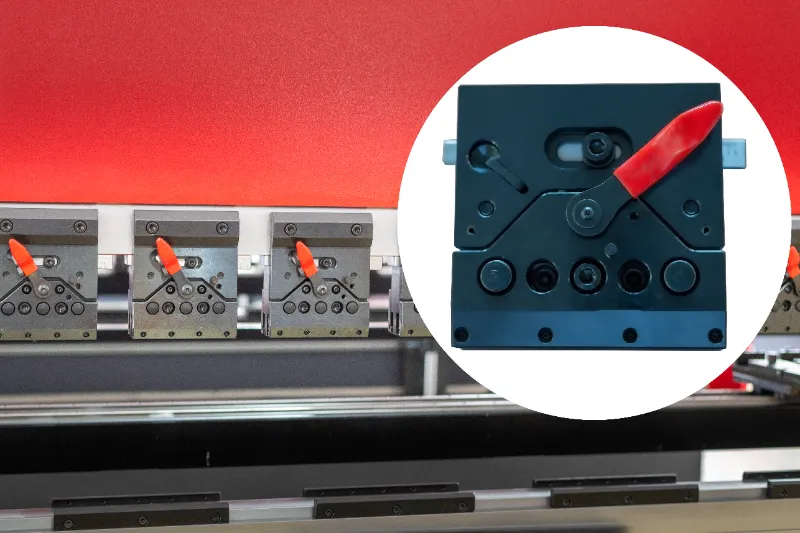

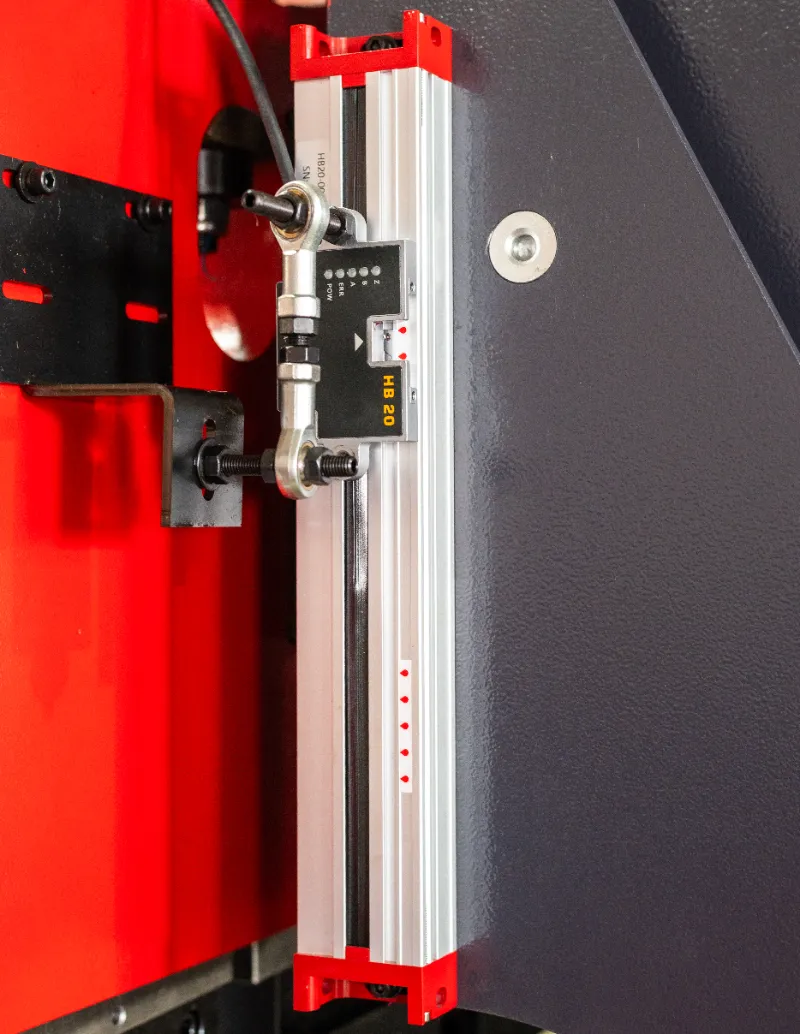

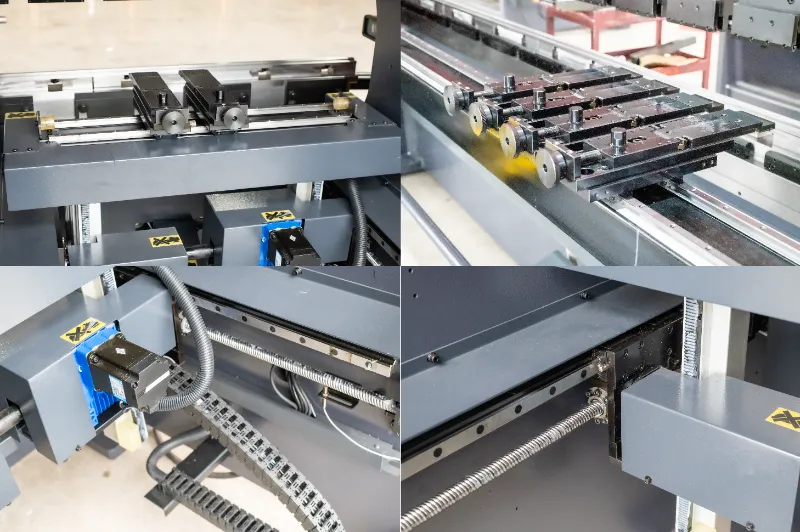

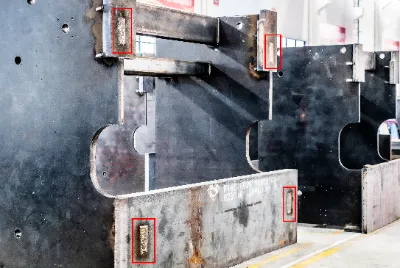

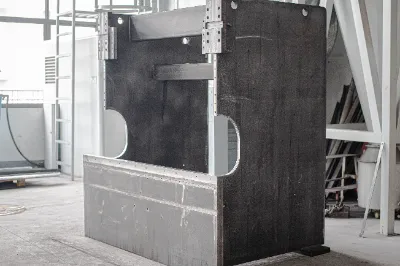

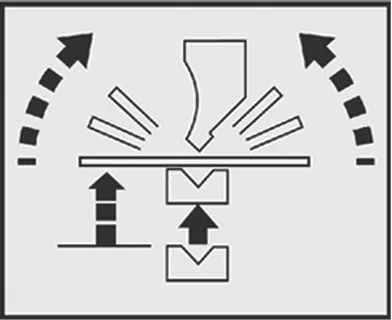

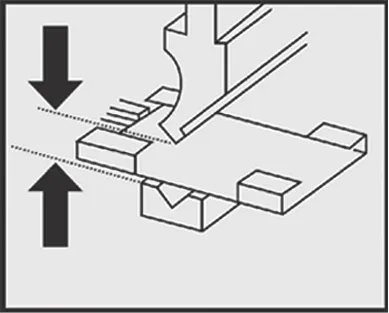

Germany's HAWE oil-electric hybrid drive boosts SH series energy efficiency by 50%, delivering 0.005mm positioning accuracy and cutting power costs by 40%. Crowning mechanism ensures consistent bending precision across 500-3,200mm widths. 5-micron magnetic scale and pressure filter reduce cycle time by 10%, hydraulic oil use by 50%, and noise.

Applications:

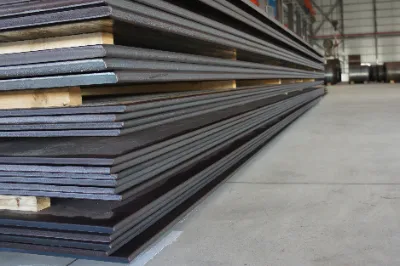

SH series targets lightweight automotive parts, new energy batteries, 5G communication frames, and aerospace titanium. Processes high-strength steel, aluminum, and stainless steel, supporting curved surfaces and flexible production. Hybrid energy-saving tech aligns with low-carbon manufacturing.