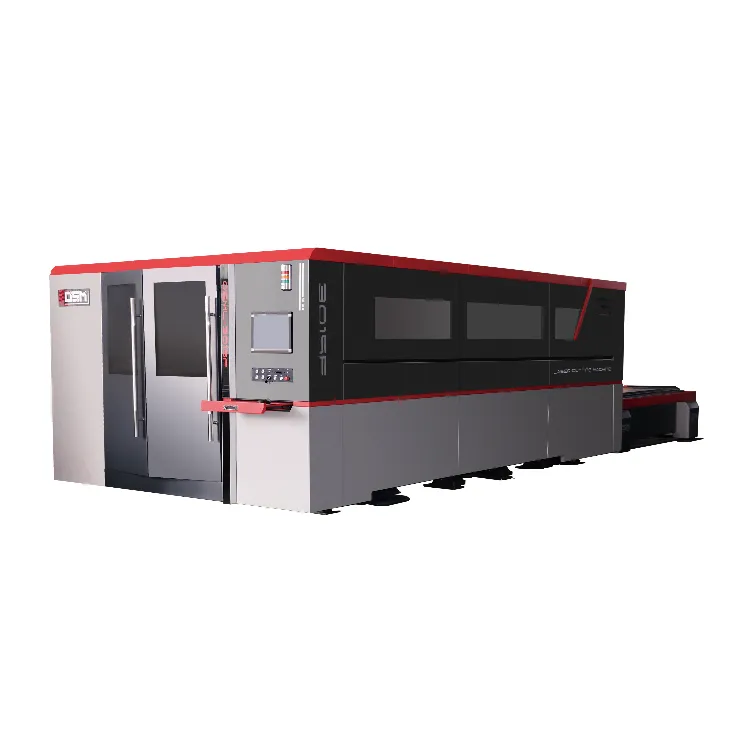

Model: OSM-FL 4015

Product Overview:

-The fiber laser cutting machine has a gantry-mounted moving beam with linear guides and a helical rack-and-pinion system driven by servo motors for precise motion. It has a dust extraction system and an automatic pallet changer, and can handle sheet sizes of up to 3×1.5m in a single cycle. Its critical components are from leading global brands, ensuring reliability and operator safety in the enclosed cutting zone.

- Ideal for processing carbon steel, stainless steel, and aluminum alloys. Combines advanced engineering with robust stability. Speeds up to 120 m/min (100 m/min composite speed) with 1G acceleration. Maintains high control accuracy. Versatile solution for industries requiring fast, precise, and cost-effective metal fabrication.