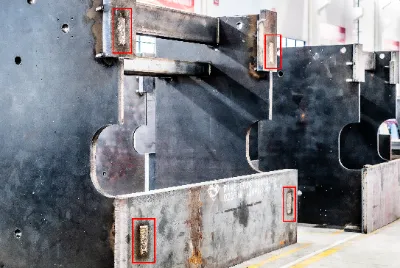

Enhanced Strength: Constructed from high-strength alloy steel, the cylinder body offers a 30% increase in pressure resistance, ensuring reliable performance under high-load and high-frequency bending operations.

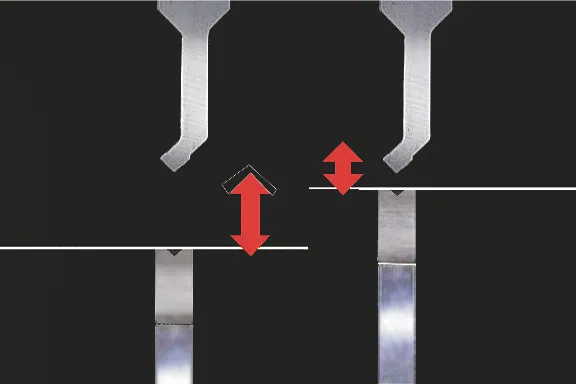

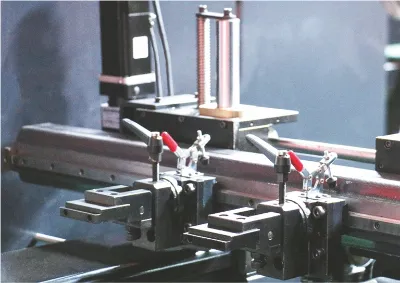

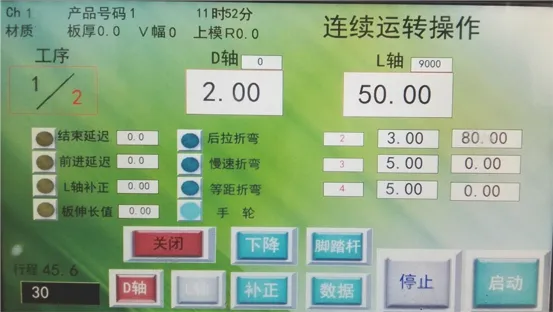

Precision Control: The advanced hydraulic control system delivers rapid response times (≤0.1 seconds) with a positioning accuracy of ±0.05 mm, guaranteeing precise bending angles.

Advanced Sealing: Utilizing nano-level sealing technology, the cylinder is highly resistant to wear and leakage, effectively doubling its service life and reducing maintenance costs.

Energy Efficiency: The low-energy-consumption hydraulic circuit design achieves a 25% energy savings compared to traditional cylinders, contributing to lower operational costs.

Overpressure Protection: Features automatic pressure relief when pressure exceeds safe limits, safeguarding the equipment from potential damage.