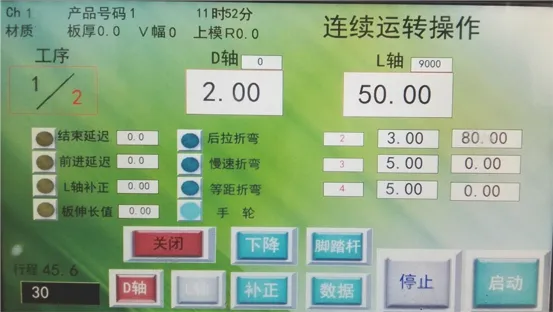

OG-35III CNC Hydraulic Down-Acting Press Brake

Model: OG-35III

Product Overview:

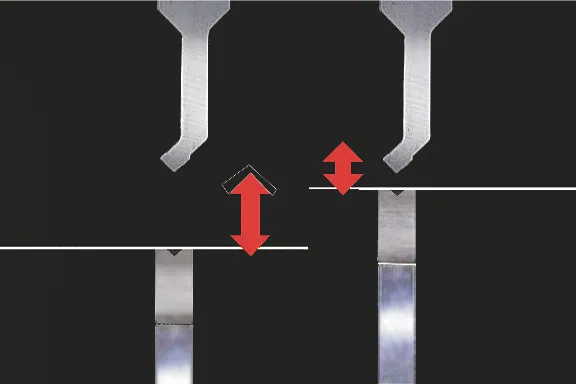

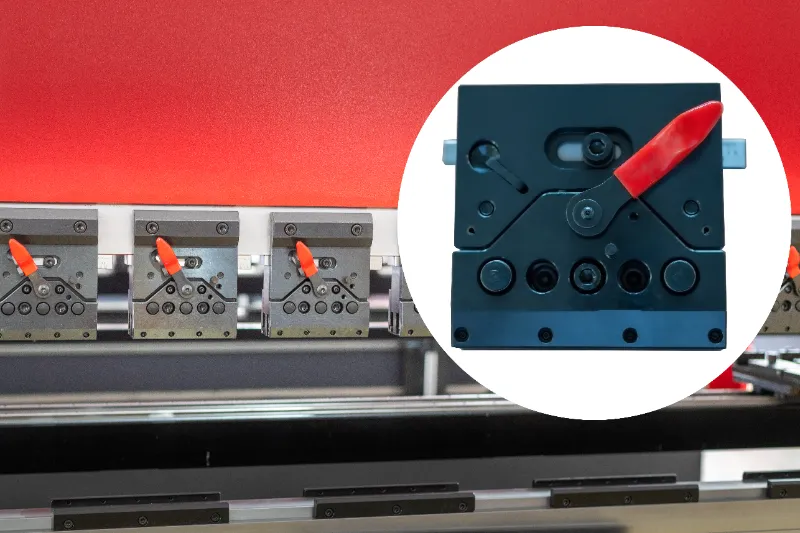

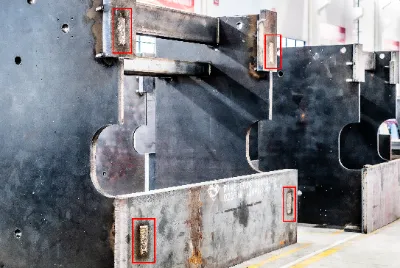

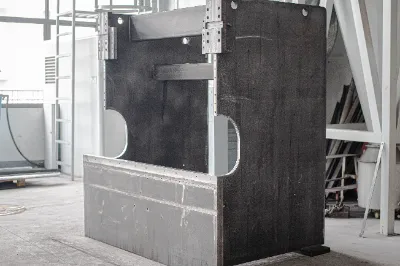

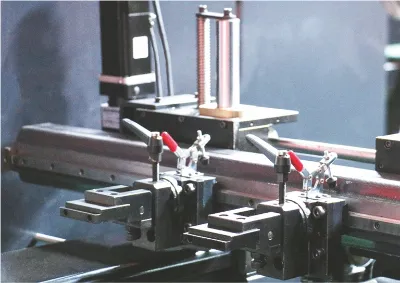

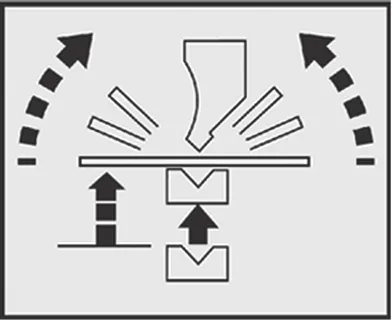

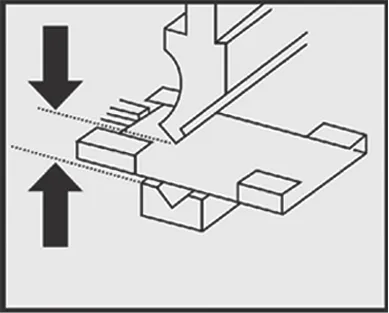

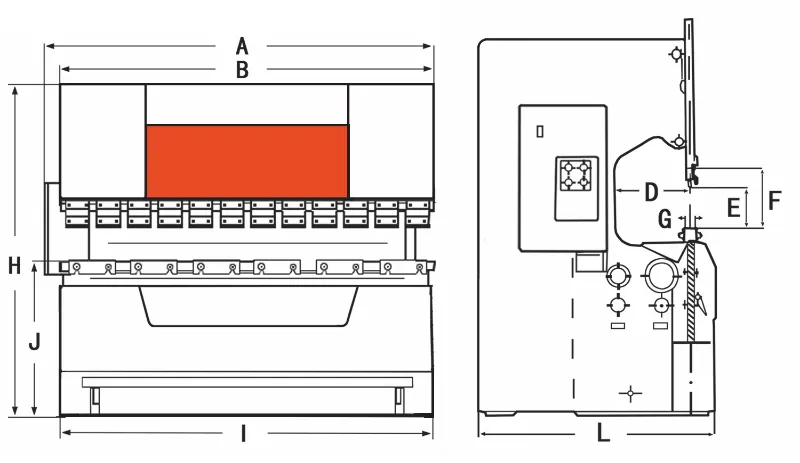

The OG series of bending machines forms multi-thickness sheet metal with high precision through a hydraulic down-acting dual-guide structure and an inclined wedge micro-adjustment compensation system. When combined with a dual-sided quick-release mold assembly and a low-fault hydraulic system, they efficiently and stably process various shaped workpieces.

Application:

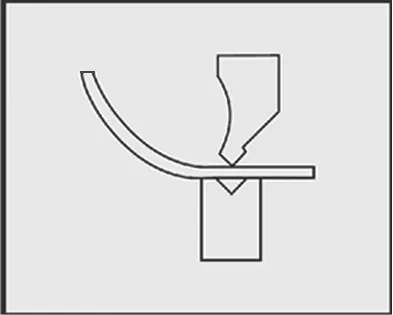

The hydraulic bending machine uses three synchronized hydraulic cylinders and FR bending technology for high precision (±0.5°) and complex curved surface processing. It is suitable for various components and fields, meeting the needs of both small-batch and mass production.