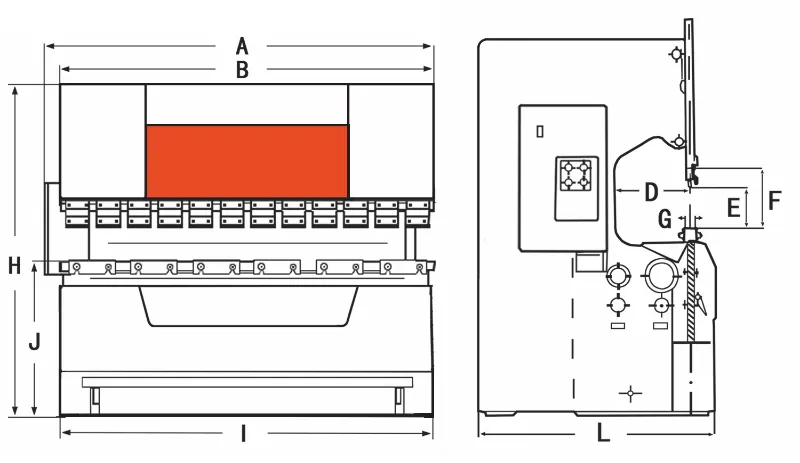

OG-100II CNC Down-Acting Hydraulic Press Brake

Model: OG-100II

Product Overview:

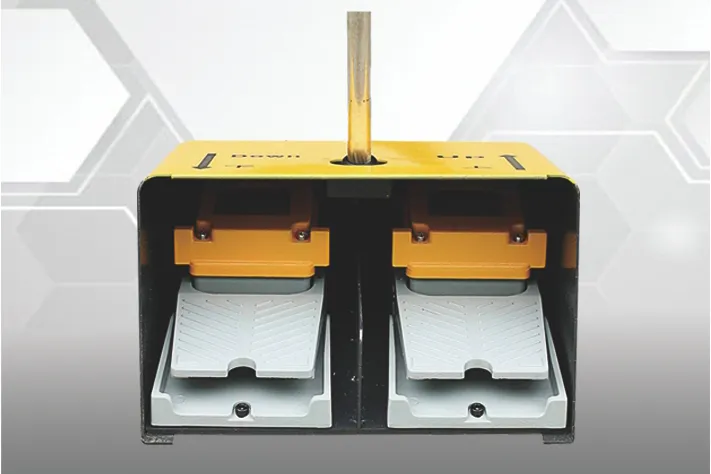

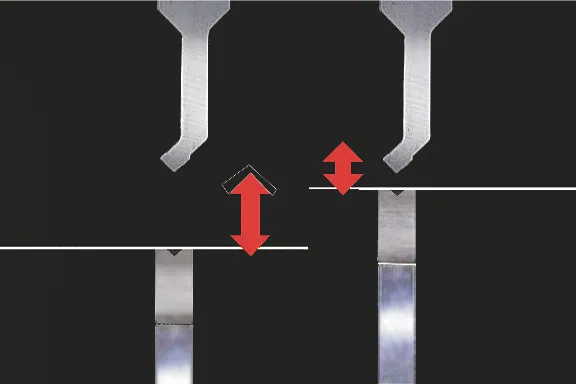

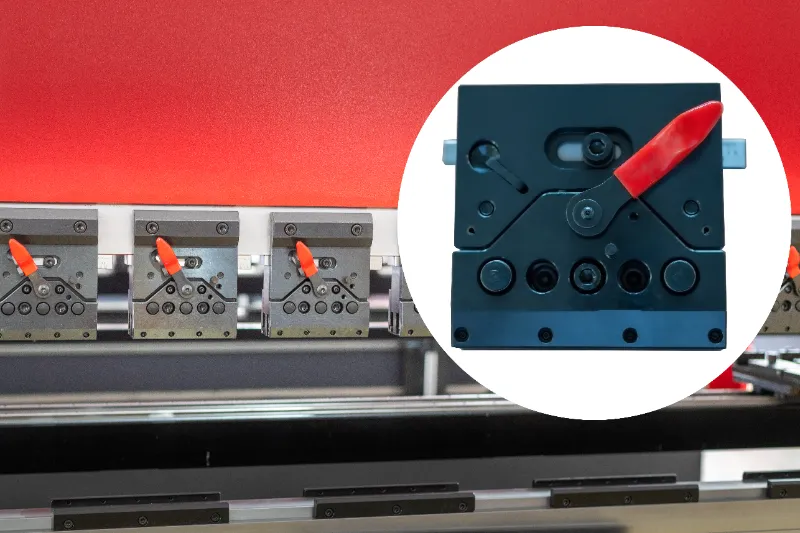

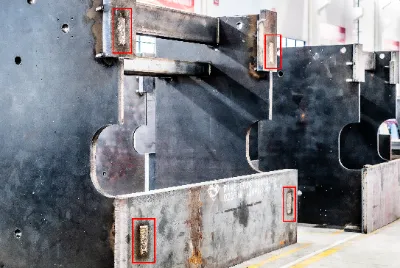

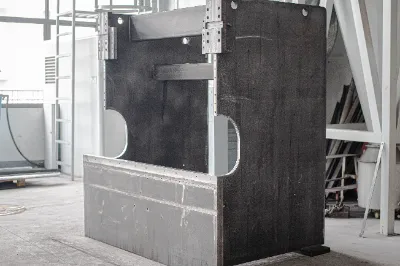

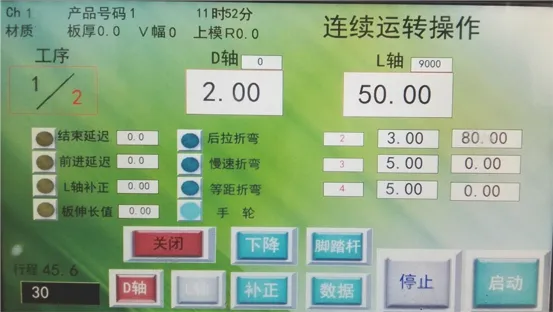

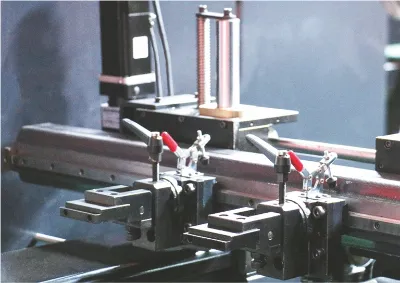

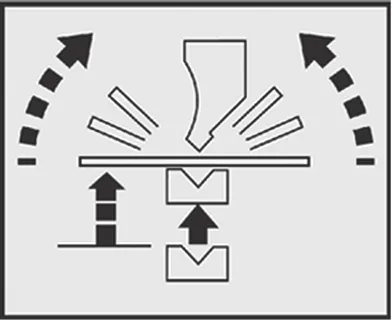

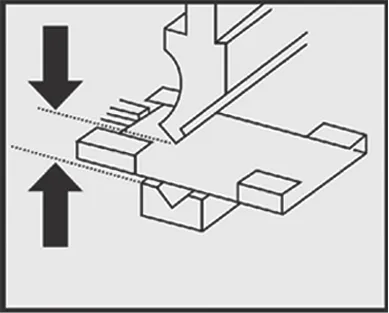

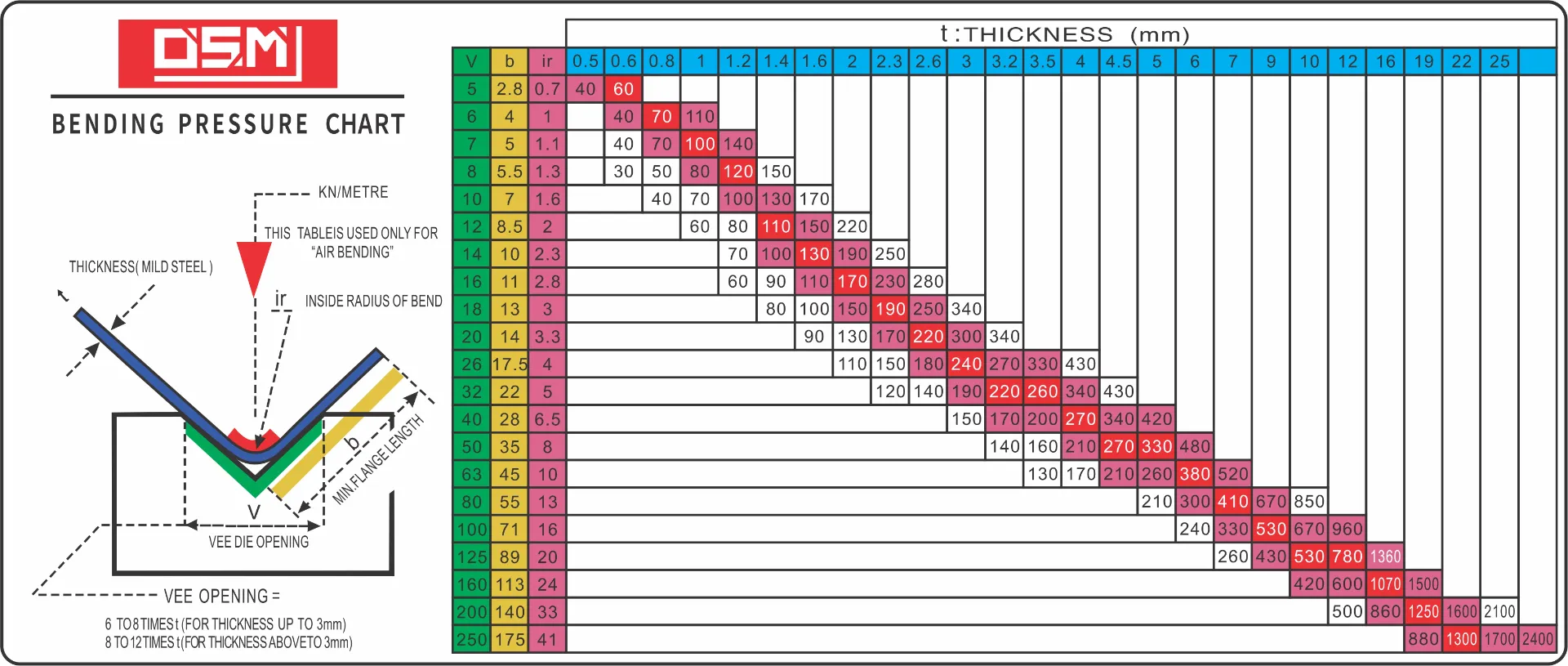

The OG series press brake forms multi-thickness sheet metal with high precision through a hydraulic down-acting dual-guide structure and an inclined wedge fine tuning crowning system. When combined with a dual-sided quick-release mold assembly and a low-fault hydraulic system, they efficiently and stably process various shaped workpieces.

Application:

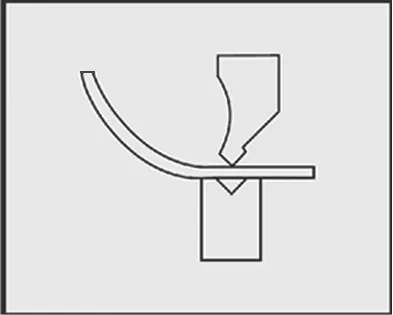

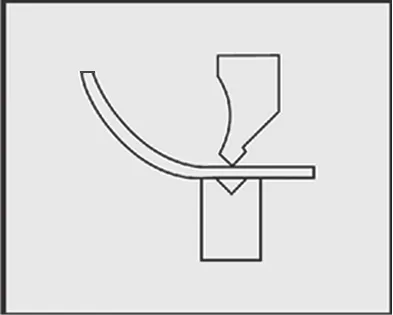

Equipped with triple hydraulic cylinders featuring synchronized drive and FR Bending Technology, this machine achieves ±0.5° ultra-high precision and complex contour processing. Ideal for automotive chassis components, new energy battery trays, 5G heat sinks, aerospace titanium alloy skins, and other irregular parts, it serves premium sectors including automotive manufacturing, new energy power batteries, optoelectronics, and aerospace.