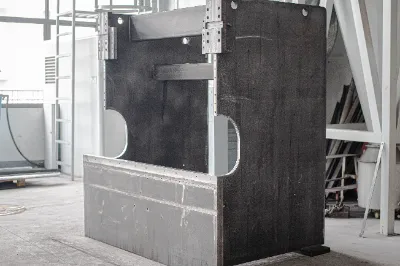

HP-13040 CNC Hydraulic Up-Acting Press Brake

Model: HP-13040

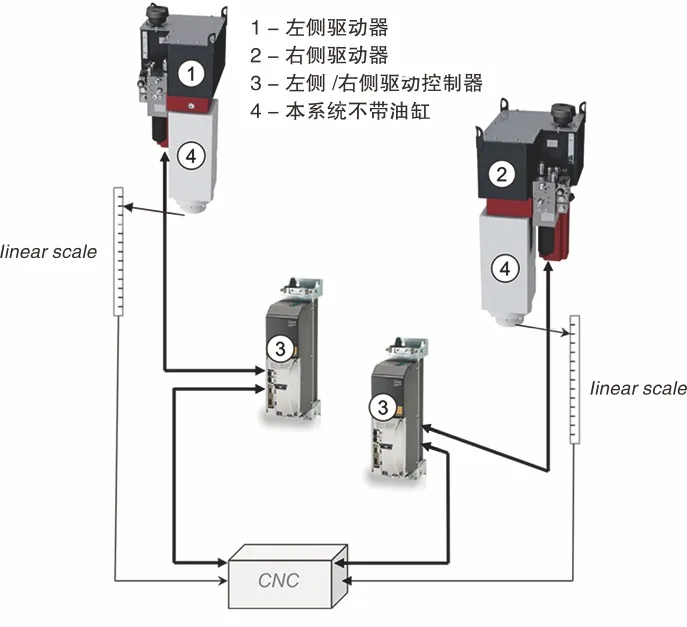

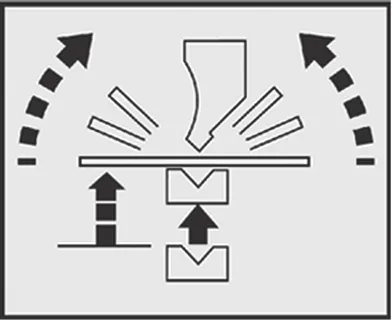

Process: Dual-closed-loop servo drives and dynamic energy optimization cut energy use by 35% and boost response by 50%. Pressure adaptive compensation ensures ±0.01mm repeatability, 99.8% uptime stability, and 40% lower operating costs.

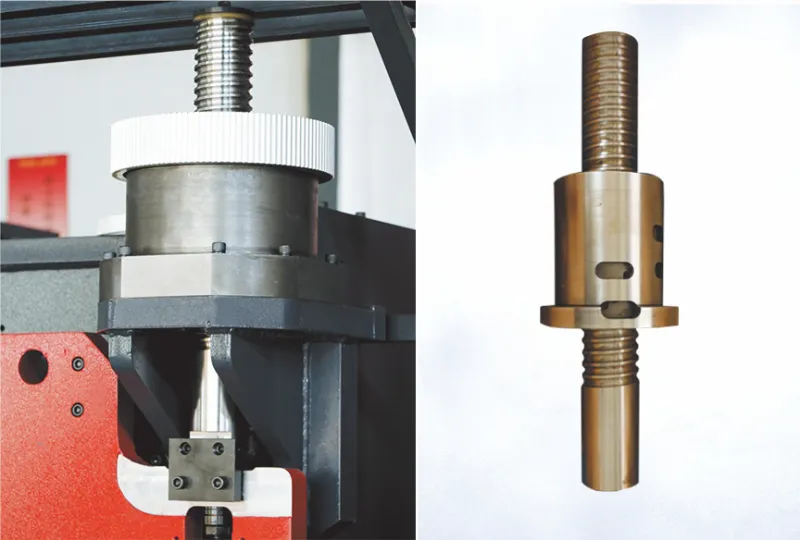

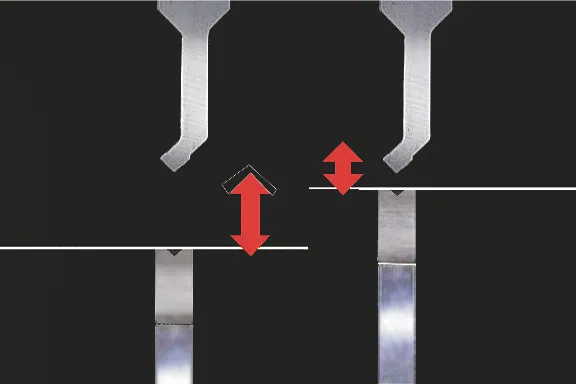

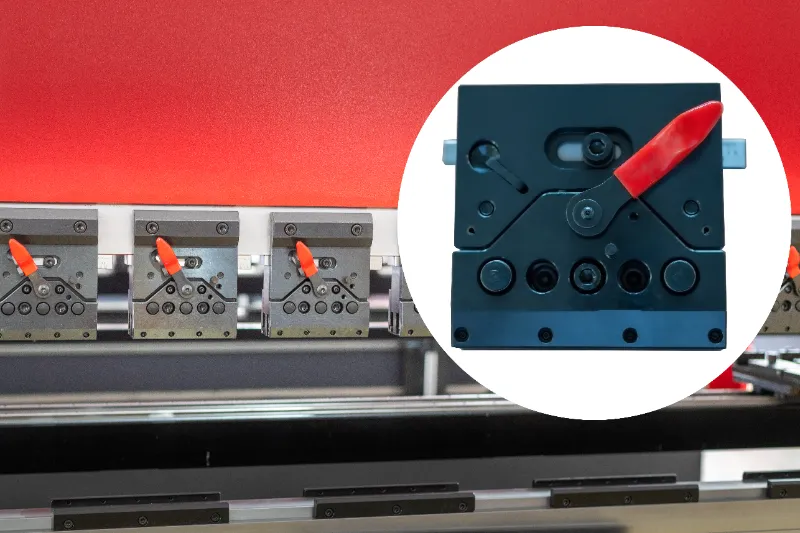

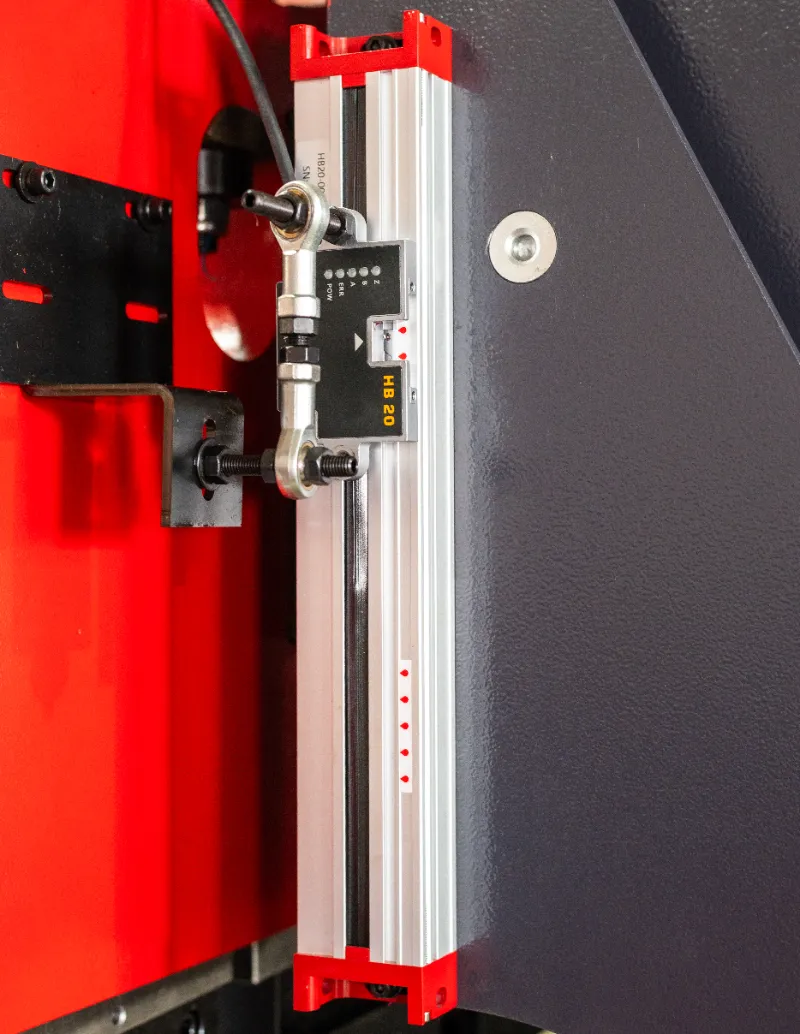

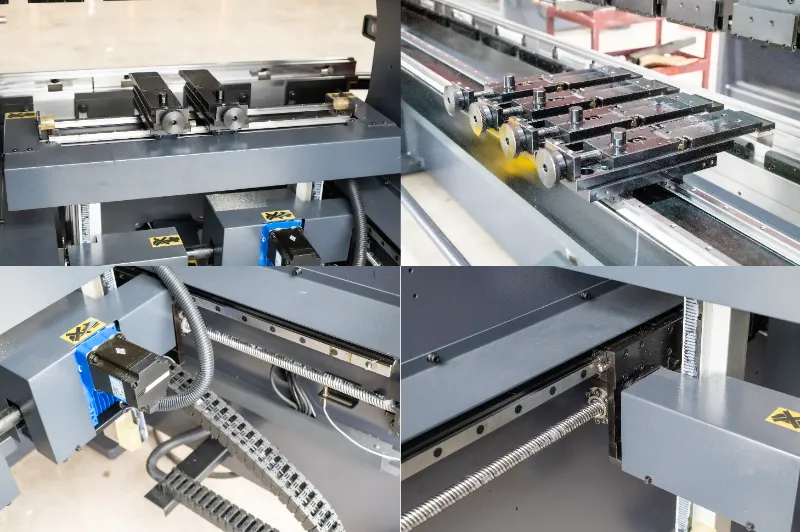

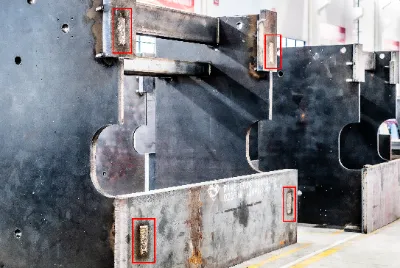

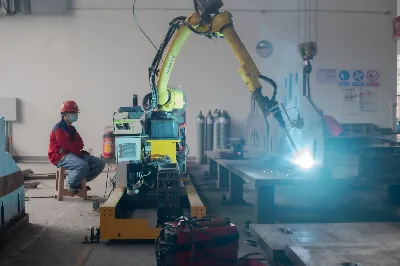

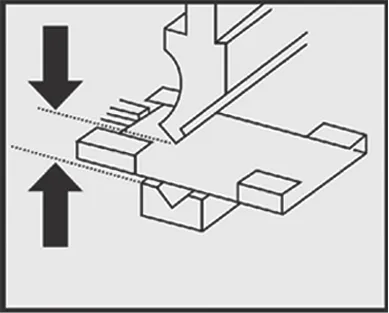

Product Overview: The HP series features Laimore/Delem/CybTouch CNC platforms with 4+1-axis standard control (6+1 optional). It is built on a rigid monoblock frame and is equipped with German HAWE/Rexroth hydraulics for tonnage and speed via pressure balancing and multi-stage efficiency. A multi-axis backgauge system enables fast part positioning, while full-loop synchronization ensures precision in high-speed forming, especially for irregular geometries.

Applications: It's ideal for vehicles, batteries, 5G chassis, and aluminum frames. It bends high-strength materials well. Modular tooling and a smart process library support flexible batch production, making it a versatile solution for sheet metal fabrication.