Elevator Thin-Panel Precision Processing System|

0.6mm Stainless Steel/Cold-Rolled Carbon Steel Bending Expert

Elevator Door Panel Mass Production Smart Line|

Carbon Steel/Stainless Steel High-Speed Forming Center

Elevator Column Components Dedicated Thick Plate Processing Center|6-20mm Carbon Steel/Stainless Steel Column Forming Powerhouse

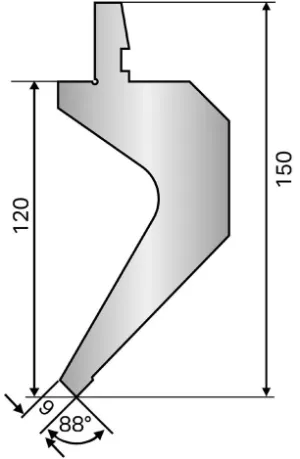

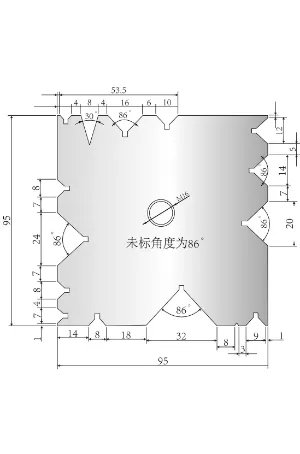

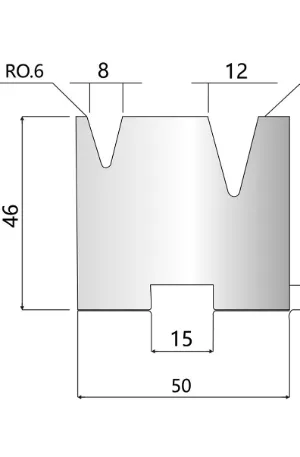

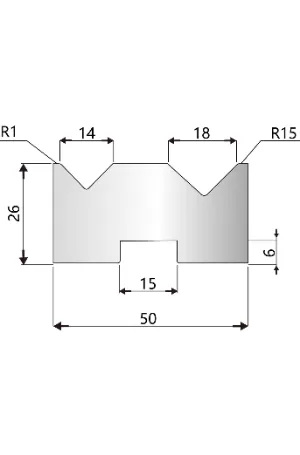

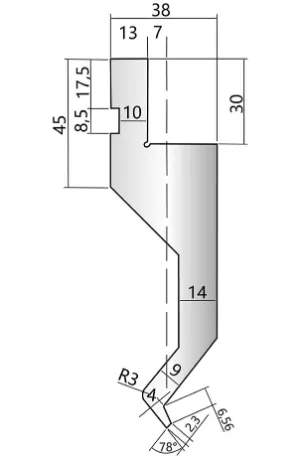

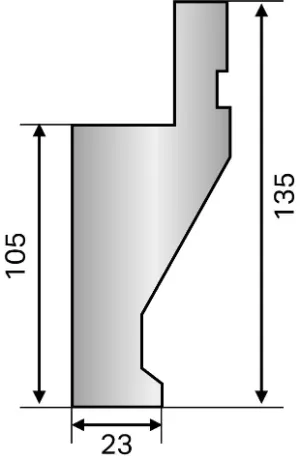

OSM press brakes achieve ultra-high precision of ±0.01mm, exemplified in elevator car panel bending where accurate angles and dimensions ensure seamless assembly. The advanced CNC system precisely controls bending parameters (angle, depth, speed) according to elevator component design requirements.

The rapid tooling change system reduces mold replacement time to under 5 minutes, significantly enhancing productivity for elevator industry's diverse, small-batch production. Under frequent bending operations, it achieves 50-80 bends per hour, meeting mass production demands.

Designed for elevator-grade stainless steel and carbon steel, the machine handles 0.4-12mm thickness ranges effortlessly. Specialized tooling enables precise bending of complex components like curved handrails and shaped door panels.

Equipped with multi-layer safety protections (light curtains, emergency stops), it ensures operator safety. The stable mechanical structure and electrical system enable quick shutdowns during anomalies, minimizing downtime and ensuring continuous elevator production.