Ultra-precision control system (±0.01mm accuracy) enables millimeter-level bending angle/depth adjustment, ensuring zero-dimensional error in cabinet components. This precision forms flawless assembly foundations and extends product lifespan significantly.

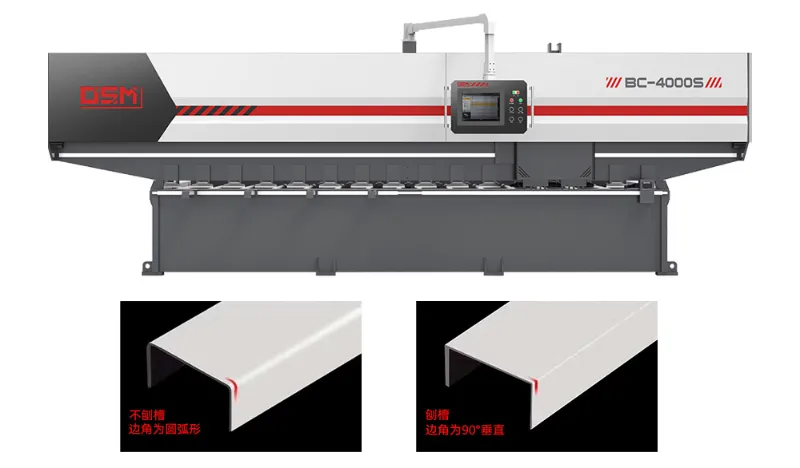

Flexible bending centers integrate full automation modules: auto-feeding, smart positioning, precise forming, and unloading. Programmable presets allow continuous production of complex shapes with automatic parameter adaptation, eliminating manual intervention and enhancing process stability.

High-precision bending eliminates fold deformation, achieving smooth, natural contours. This craftsmanship elevates cabinet aesthetics to precision furniture standards, enhancing market competitiveness through superior visual quality.

Smart control systems optimize material usage via data-driven path calculation, reducing raw material waste by 15-20% compared to traditional methods. This cost-saving approach aligns with sustainable manufacturing principles.