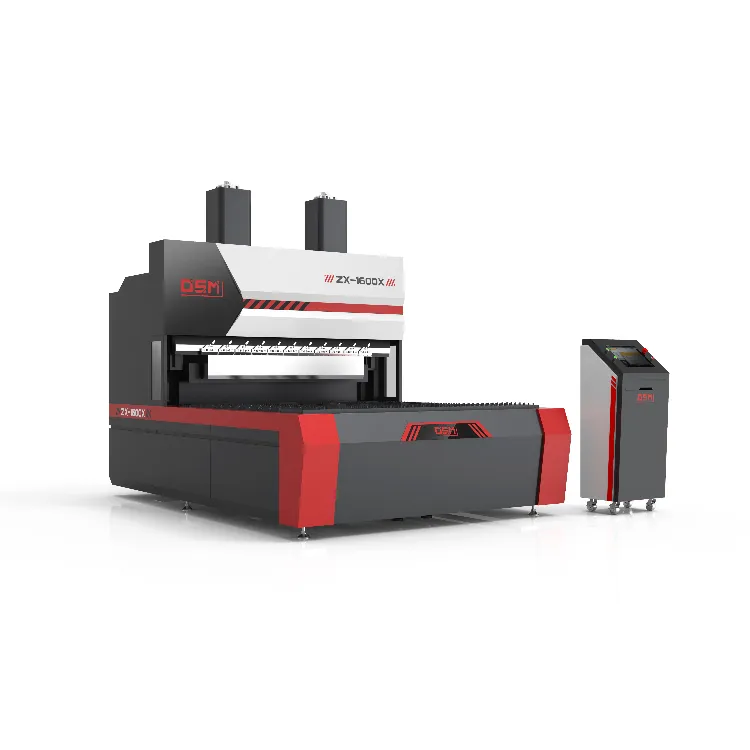

Model: ZX-1600X

Product Overview:

The ZX Series adapts gantry-frame design paired with industrial-grade CNC system and laser positioning, automatically adjusts to material properties (steel, aluminum, stainless steel), achieving 0.5s/step bending speeds and 30s tooling changes. Its servo drive and control system allows precise synchronization of multi-axis linkage, increasing machining efficiency by 50%, reducing energy consumption by 35%, and supporting complex curved surfaces in a single molding. With automation and simplified operation, the operation can be fast and smooth.

Applicable:

This is applicable in the automotive industry, the aerospace industry, 5G communication, intelligent home appliances etc,. It is well suited to the needs of new energy, electronic communications and other emerging markets, helping enterprises to respond quickly.